Free Shipping on Selected Items

- Heyn News

- The Top 3 Reasons Why a Manufacturing Business Should Invest in Overhead Rigging Systems

Engineering

The Top 3 Reasons Why a Manufacturing Business Should Invest in Overhead Rigging Systems

"Discover the Benefits: Top 3 Reasons Why Manufacturing Businesses Should Consider Automation. From enhanced efficiency to cost savings, explore the advantages of automation for your manufacturing operations. Learn more at Heyn and optimize your business for success."

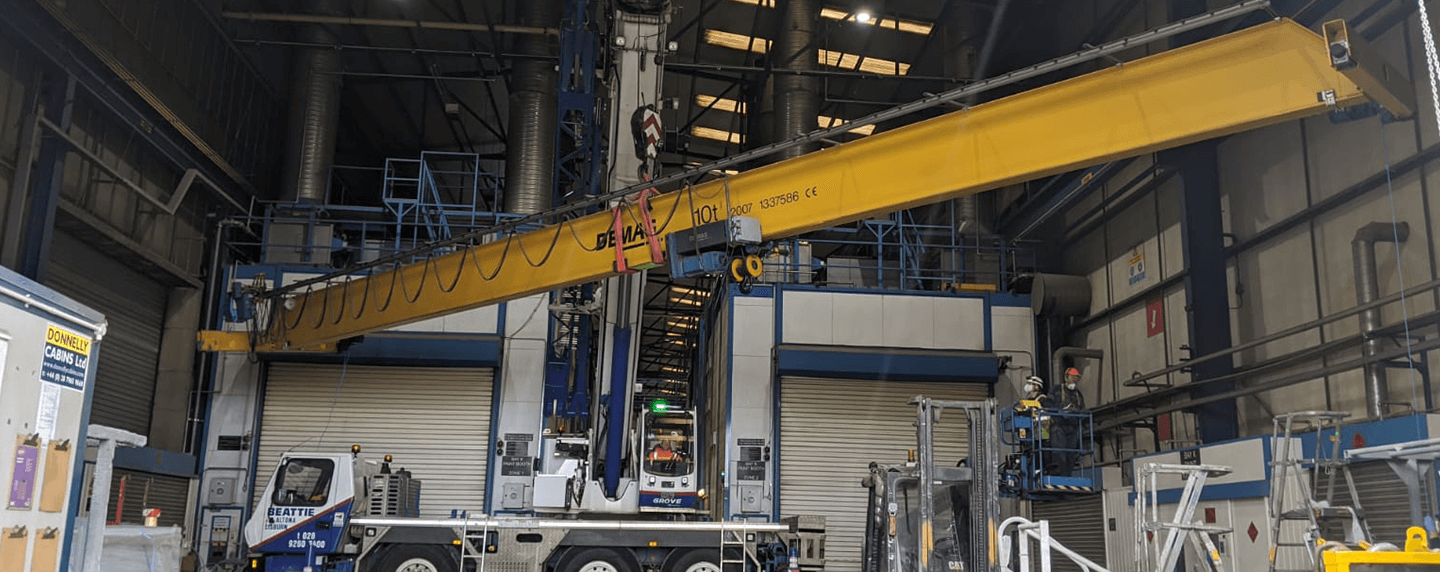

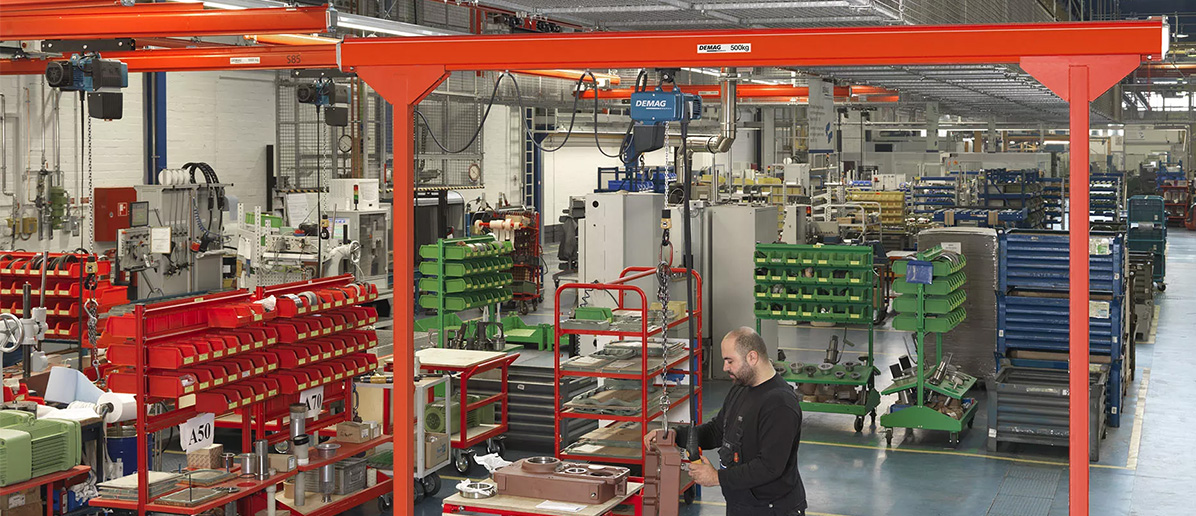

In today's rapidly evolving manufacturing landscape, businesses are constantly seeking innovative solutions to enhance their operational efficiency, productivity, and safety standards. One such solution gaining significant attention is the overhead rigging system. This advanced technology offers numerous benefits that can greatly impact a manufacturing business. In this article, we will explore the top three reasons why investing in an overhead rigging system is a smart move for any manufacturing enterprise.

Improved Efficiency and Productivity:

Efficiency and productivity are vital factors for success in the manufacturing industry. Overhead rigging systems provide a range of features that optimise workflow and streamline operations, leading to enhanced efficiency and productivity. Here's how:

a. Flexible Material Handling:

Overhead rigging systems offer the ability to lift, move, and position heavy materials and equipment with ease. Whether it is raw materials, work-in-progress items, or finished products, the overhead rigging system enables efficient material handling throughout the production process. By eliminating manual handling and reducing downtime associated with material transportation, manufacturing businesses can significantly increase their overall productivity.

b. Optimised Space Utilization:

Traditional floor-based material handling methods often lead to cluttered workspaces, limiting the available floor area. However, overhead rigging systems utilise the vertical space, freeing up valuable floor space for other operations. This optimal space utilisation allows businesses to maximise their production capacity and potentially introduce new machinery or expand their manufacturing lines without having to invest in additional floor space.

c. Quick and Precise Positioning:

Overhead rigging systems are designed for precise positioning of materials, reducing the risk of errors, and improving overall operational accuracy. The system's controls enable operators to move heavy loads smoothly and effortlessly, facilitating seamless alignment with workstations, assembly lines, or storage areas. This precision not only saves time but also minimises the likelihood of damage to products and equipment.

Enhanced Workplace Safety:

Worker safety is a top priority in any manufacturing environment. Overhead rigging systems play a pivotal role in ensuring a safer workplace by mitigating potential hazards and reducing the risk of accidents. Here is how they contribute to enhanced safety:

a. Reduced Manual Lifting:

One of the most common causes of workplace injuries in manufacturing is related to manual lifting and carrying of heavy objects. Overhead rigging systems eliminate the need for manual lifting, significantly reducing the risk of musculoskeletal injuries and strain on employees. Workers can focus on operating the system safely, while the heavy lifting is taken care of by the machinery.

b. Increased Stability and Load Capacity:

Overhead rigging systems are engineered to provide high load-bearing capacity and stability. They are designed to handle heavy loads that would otherwise be challenging or unsafe for human operators. By using robust rigging equipment, manufacturing businesses can ensure that materials and equipment are lifted and moved securely, minimising the risk of accidents or damage.

c. Compliance with Safety Standards:

Overhead rigging systems are built to meet stringent safety standards and regulations. They incorporate safety features such as limit switches, emergency stop buttons, and anti-collision systems to prevent accidents and protect both personnel and assets. Investing in an overhead rigging system ensures that businesses stay compliant with safety requirements, providing peace of mind and reducing liability risks.

Cost Savings and Return on Investment (ROI):

Investing in an overhead rigging system offers long-term cost savings and a favourable return on investment for manufacturing businesses. Here are some key cost-related advantages:

a. Increased Operational Efficiency:

By improving material handling processes, reducing downtime, and optimising space utilization, overhead rigging systems contribute to overall operational efficiency. This efficiency translates into cost savings through reduced labour costs, enhanced throughput, and minimized material wastage.

b. Reduced Maintenance and Repair Expenses:

Modern overhead rigging systems are designed for durability and require minimal maintenance. Regular inspections and preventive maintenance ensure their smooth operation and any potential issues can be addressed promptly. By minimizing downtime and the need for costly repairs, businesses can save on maintenance expenses and keep their operations running smoothly.

c. Scalability and Adaptability:

Overhead rigging systems are highly versatile and can be easily adapted to accommodate changing production needs. Whether it's handling heavier loads, expanding the facility, or reconfiguring the production layout, the system can be adjusted accordingly. This scalability allows businesses to avoid significant investments in new equipment and infrastructure, resulting in substantial cost savings in the long run.

Conclusion:

Investing in an overhead rigging system offers manufacturing businesses a competitive edge by enhancing efficiency, improving workplace safety, and delivering cost savings. The flexibility, precision, and optimised space utilization provided by these systems contribute to increased productivity and throughput. Furthermore, the enhanced safety features reduce the risk of workplace accidents, ensuring the well-being of employees. With long-term cost savings and a favourable return on investment, it is clear that an overhead rigging system is a strategic investment for any manufacturing enterprise looking to thrive in today's dynamic industrial landscape.

Latest

Latest Posts

Keep up to date with the latest industry news, Heyn Articles and going's on

View all posts

09 March 2023

Heyn Engineering using Hilti tools and consumables for maximum proficiency

Heyn Engineering are delighted to partner with Hilti across their tooling fleet programme and more recently with the Hilti ON! Track management system.

10 July 2023

Heyn Engineering team tests the original crane in Titanic's Pump House ahead of huge transformation

Heyn Engineering has recently been honoured with the job of testing the original crane which rests in the Pump House at Titanic’s Dock in the Titanic Quarter on behalf of Titanic Distillers. Titanic Distillers produce a premium Irish whiskey that is now sought after worldwide and is a testament to the ever-growing popularity of Irish whiskies today.

28 August 2023

Heyn Forktruck receives award for success with HELI Forklifts

"Celebrating Success: Heyn Forktruck Awarded for Outstanding Achievement with HEL. Discover how our expertise in material handling led to this prestigious recognition. Learn about our commitment to excellence in forklift solutions at Heyn."

28 August 2023

The Advantages of Switching to a Heli Lithium-Ion Battery-Powered Fork Truck

28 August 2023

Promoting Eco-Friendly Practices: Embracing Recycled Plastic Products in Public Areas

Embrace Recycling and Eco-Friendly Practices. Discover the Importance of Recycling Initiatives and Sustainable Choices. Join Heyn in Promoting a Greener Future for Businesses and Communities.

28 August 2023

Ensuring Safety and Productivity: Heyn Engineering's Certifying Programme LOLER for High-Quality Load Lifting Equipment

Prioritising Safety and Productivity: Heyn Engineering's Commitment Unveiled. Discover How Our Expertise Enhances Workplace Safety While Boosting Operational Productivity. Learn More About Heyn's Engineering Excellence and Innovative Solutions.

28 August 2023

Enhancing Efficiency and Safety: The Benefits of Installing a Wireless Forklift Camera to Your Truck

28 August 2023

Heyn Forktrucks: Pioneering Cost-Effective Electric Forklifts Throughout Northern Ireland

28 August 2023

Congratulations on embarking on a career in engineering!

29 August 2023

HSE Guidance - No Grace Period for LOLER Testing

29 August 2023

Identifying the Lifespan of your Tractel Height Safety Equipment

29 August 2023

Our guide to looking after and maintaining your Diesel/LPG Forklift truck

30 August 2023

Heyn's Warehouse Safety Tips

30 August 2023

Webbing Slings versus Round Slings…what are the differences?

30 August 2023

Heyn Forktrucks – Exclusive Heli Dealers for Northern Ireland

Explore the Power of Heli Forklifts in Northern Ireland. Discover Reliable and Efficient Material Handling Solutions with Heyn. Stay Updated with Latest Forklift Insights and News

05 September 2023

Flanagan Flooring Welcome Five New Heli Trucks To Their Fleet

14 September 2023

Transforming Wind Turbines into Sustainable Footbridges: A Remarkable Innovation by Queen's University Belfast

Read how engineers at Queens University Belfast are transforming wind turbine blades, which are set to be landfilled or incinerated, into footbridges that can hold the weight of a 30-tonne digger.

16 October 2023

Enhancing Outdoor Learning Spaces with Heyn Environmental and Recycled Plastic Furniture

Heyn Environmental are partnering with schools across Northern Ireland to promote outdoor learning and improving their outdoor spaces

13 November 2023

Height Safety Harnesses – how to choose the correct one and fit it safely

14 November 2023

VErope Special Wire Ropes in Northern Ireland

28 November 2023

Heyn's Top Tips for Rainproofing Your Forklift Truck

29 November 2023

The Crucial Role of Grit, Salt, and Spreaders: Preparing Businesses for Winter

29 November 2023

Prepare Your Forklift For The Winter Season

08 December 2023

Christmas 2023

21 December 2023

Merry Christmas from all at Heyn HS

10 January 2024

Forklift Truck Maintenance

16 January 2024

Thorough Examination Services

21 February 2024

Heli Lithium-Lite Forklift Range

04 March 2024

Machine Movers & Riggers – What Do They Do?

07 March 2024

HSENI launch a campaign for safe driving on construction sites as part of #DriveDangerOut.

12 March 2024

Keeping Pedestrians Safe in the Workplace

12 March 2024

Safeguarding Lives: Prioritising Safe Use of Lift Trucks in the Workplace

15 March 2024

Optimising Workplace Safety and Efficiency with Heyn Forktrucks and Engineering Services

18 March 2024

Ensuring Workplace Safety: The Crucial Role of Testing Lifting Equipment

17 April 2024

Welsh Government Introduces New Workplace Recycling Legislation

22 April 2024

How UK Companies Can Embrace Recycling to Combat Plastic Pollution in the Workplace

15 May 2024

Simpler Recycling in England- A Brief Overview

28 May 2024

We have developed an online LOLER inspection and certification system

07 June 2024

The Benefits of Recycled Plastic: A Sustainable Solution for the Future

07 June 2024

The Smoking Ban and Workplace Compliance: A Guide for Businesses

19 September 2024

Cycle to School Week: Encouraging a Healthier, Greener Future

21 November 2024

Christmas and New Year 2024

26 November 2024

Heyn Engineering Excited to Expand with SEW Stainless Steel Gear Units

26 November 2024

Winter Safety Checklist for Facilities Managers in the UK

12 December 2024

The New Waste Legislation Coming in March 2025: What You Need to Know

17 December 2024

Christmas 2024

06 January 2025

Heyn Engineering provides solutions for manufacturing and logistics

13 January 2025

Heyn Engineering : Load Testing Services

13 January 2025

The Benefits of Greenskeeper Rubber Matting for Golf Courses During Winter

17 January 2025

Simpler Recycling: Don't get caught out with the new legislation

24 January 2025

How to Prevent Damage to Cranes in High Winds: Preparing for Storm Eowyn and Beyond

27 January 2025

Labelling & Identification Solutions by Heyn Environmental

11 February 2025

Rising Car Crime in the UK: Protecting Your Vehicle at Home and in Public Spaces

18 March 2025

Enhance Your Leisure and Caravan Parks with Heyn Environmental

13 May 2025

How Heyn Environmental Helps Local Councils and Community Centres Get Summer-Ready

20 May 2025

Protecting Lives at Height: Why Fall Arrest Systems Are Essential for Workplace Safety

31 July 2025

Celebrating a 50-Year Partnership: Heyn Engineering & Demag Cranes

01 October 2025

Heyn Engineering Leads Historic Move of Spanish Armada Collection

14 November 2025

Proud to Announce: Heyn Engineering & Heyn Forktrucks Achieve Alcumus SafeContractor Accreditation

21 November 2025

Essential Winter Safety Tips