Free Shipping on Selected Items

- Heyn News

- Heyn's Warehouse Safety Tips

Engineering/Environmental/Forktrucks

Heyn's Warehouse Safety Tips

Workers who stand for long time periods in jobs such as packing or machine operating can get strained feet, legs, and back due to the hard floors warehouses typically have to accommodate forklifts and pallet trucks. However, placing anti-fatigue mats around worker areas will provide a softer floor and reduce tiredness, strain, and fatigue.

Wet Floors due to cleaning, open doorways, and machinery are all additional risks in the warehouse, by placing non-slip matting in these high-risk areas it can help prevent the risk of slips and falls. It is also recommended that entrance matting be used in wet weather to minimise trip hazards and keep floors dry. It is also important to check for potholes regularly and arrange for any to be fixed if found as an uneven floor could increase the risk of accidents in the workplace. Cords shouldn't be stretched across aisles or placed under carpets and all aisles should be kept clear of tripping hazards. Carpets should be secure and free of tears, lumps and loose pieces.

Visibility:

Forklifts and other industrial vehicles in warehouses can be potentially dangerous, especially if visibility is low. It is important vehicle operators have a clear view of their surroundings to minimise the risk of collisions with other vehicles or workers on foot. The use of mirrors at the end of pallet racking aisles or in other blind spots of a warehouse can show forklift drivers what’s waiting around the corner.

Creating safe walkways for pedestrians will also reduce the risk of injuries both indoors and outdoors. This can be done by separating the path with a physical barrier (eg: a fence or line of bollards) or with the use of painted lines on the floor, arrows and other floor signs to mark transport routes, risk zones and fire exits/escape roots.

Wearing Personal Protective Equipment would also increase visibility and safety within the warehouse. Equipment such as hard hats, high visibility clothing, safety shoes, goggles and ear defenders are all beneficial items to have when working in a warehouse depending on your needs however hard hats and high visibility clothing are essential in most warehouse sites.

Bookcases, Shelving and Storage:

Bookcases and shelves should not be overloaded and heavy storage shelving should be secured to walls. File drawers and cabinets should be closed when not in use and bookcases and cabinets should be secured against tipping. Steps stools and ladders should be properly used when needed to access high shelving and put away when not in use to keep floors clear.

Electrical Safety:

Electrical outlets should not be overloaded and all cords and plugs should be in good condition. Extension cords should not be substituted for permanent wiring.

It is essential to anticipate potential dangers in the workplace to minimise the risk of accidents, warehouses have a lot of open space and kindling meaning that fire can spread extremely rapidly. Not only do fires damage your warehouse and potentially harm workers but they also lead to the loss of valuable resources and production time. In fact, many businesses never fully recover from a serious fire. Frequent evacuation drills should be carried out to ensure personnel know what to do in such circumstances and that this information stays fresh in their minds. Fire alarms should also be tested weekly and there should be at least 1 designated Fire Warden. Fire extinguishers should be easily accessible and fully charged at all times, it is a legal requirement to ensure escape routes are clearly marked, easy to access, wide enough and free of obstacles.

For more safety tips see our below guides for reducing risks in the workplace:

Latest

Latest Posts

Keep up to date with the latest industry news, Heyn Articles and going's on

View all posts

09 March 2023

Heyn Engineering using Hilti tools and consumables for maximum proficiency

Heyn Engineering are delighted to partner with Hilti across their tooling fleet programme and more recently with the Hilti ON! Track management system.

10 July 2023

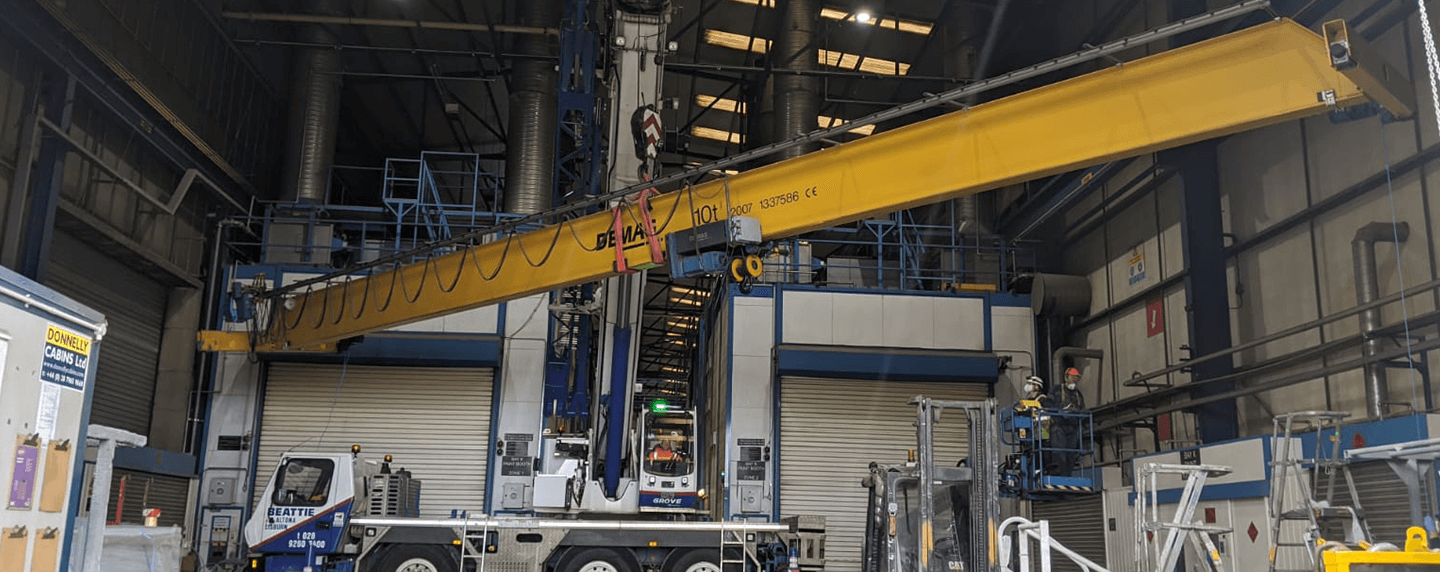

Heyn Engineering team tests the original crane in Titanic's Pump House ahead of huge transformation

Heyn Engineering has recently been honoured with the job of testing the original crane which rests in the Pump House at Titanic’s Dock in the Titanic Quarter on behalf of Titanic Distillers. Titanic Distillers produce a premium Irish whiskey that is now sought after worldwide and is a testament to the ever-growing popularity of Irish whiskies today.

28 August 2023

Heyn Forktruck receives award for success with HELI Forklifts

"Celebrating Success: Heyn Forktruck Awarded for Outstanding Achievement with HEL. Discover how our expertise in material handling led to this prestigious recognition. Learn about our commitment to excellence in forklift solutions at Heyn."

28 August 2023

The Top 3 Reasons Why a Manufacturing Business Should Invest in Overhead Rigging Systems

"Discover the Benefits: Top 3 Reasons Why Manufacturing Businesses Should Consider Automation. From enhanced efficiency to cost savings, explore the advantages of automation for your manufacturing operations. Learn more at Heyn and optimize your business for success."

28 August 2023

The Advantages of Switching to a Heli Lithium-Ion Battery-Powered Fork Truck

28 August 2023

Promoting Eco-Friendly Practices: Embracing Recycled Plastic Products in Public Areas

Embrace Recycling and Eco-Friendly Practices. Discover the Importance of Recycling Initiatives and Sustainable Choices. Join Heyn in Promoting a Greener Future for Businesses and Communities.

28 August 2023

Ensuring Safety and Productivity: Heyn Engineering's Certifying Programme LOLER for High-Quality Load Lifting Equipment

Prioritising Safety and Productivity: Heyn Engineering's Commitment Unveiled. Discover How Our Expertise Enhances Workplace Safety While Boosting Operational Productivity. Learn More About Heyn's Engineering Excellence and Innovative Solutions.

28 August 2023

Enhancing Efficiency and Safety: The Benefits of Installing a Wireless Forklift Camera to Your Truck

28 August 2023

Heyn Forktrucks: Pioneering Cost-Effective Electric Forklifts Throughout Northern Ireland

28 August 2023

Congratulations on embarking on a career in engineering!

29 August 2023

HSE Guidance - No Grace Period for LOLER Testing

29 August 2023

Identifying the Lifespan of your Tractel Height Safety Equipment

29 August 2023

Our guide to looking after and maintaining your Diesel/LPG Forklift truck

30 August 2023

Webbing Slings versus Round Slings…what are the differences?

30 August 2023

Heyn Forktrucks – Exclusive Heli Dealers for Northern Ireland

Explore the Power of Heli Forklifts in Northern Ireland. Discover Reliable and Efficient Material Handling Solutions with Heyn. Stay Updated with Latest Forklift Insights and News

05 September 2023

Flanagan Flooring Welcome Five New Heli Trucks To Their Fleet

14 September 2023

Transforming Wind Turbines into Sustainable Footbridges: A Remarkable Innovation by Queen's University Belfast

Read how engineers at Queens University Belfast are transforming wind turbine blades, which are set to be landfilled or incinerated, into footbridges that can hold the weight of a 30-tonne digger.

16 October 2023

Enhancing Outdoor Learning Spaces with Heyn Environmental and Recycled Plastic Furniture

Heyn Environmental are partnering with schools across Northern Ireland to promote outdoor learning and improving their outdoor spaces

13 November 2023

Height Safety Harnesses – how to choose the correct one and fit it safely

14 November 2023

VErope Special Wire Ropes in Northern Ireland

28 November 2023

Heyn's Top Tips for Rainproofing Your Forklift Truck

29 November 2023

The Crucial Role of Grit, Salt, and Spreaders: Preparing Businesses for Winter

29 November 2023

Prepare Your Forklift For The Winter Season

08 December 2023

Christmas 2023

21 December 2023

Merry Christmas from all at Heyn HS

10 January 2024

Forklift Truck Maintenance

16 January 2024

Thorough Examination Services

21 February 2024

Heli Lithium-Lite Forklift Range

04 March 2024

Machine Movers & Riggers – What Do They Do?

07 March 2024

HSENI launch a campaign for safe driving on construction sites as part of #DriveDangerOut.

12 March 2024

Keeping Pedestrians Safe in the Workplace

12 March 2024

Safeguarding Lives: Prioritising Safe Use of Lift Trucks in the Workplace

15 March 2024

Optimising Workplace Safety and Efficiency with Heyn Forktrucks and Engineering Services

18 March 2024

Ensuring Workplace Safety: The Crucial Role of Testing Lifting Equipment

17 April 2024

Welsh Government Introduces New Workplace Recycling Legislation

22 April 2024

How UK Companies Can Embrace Recycling to Combat Plastic Pollution in the Workplace

15 May 2024

Simpler Recycling in England- A Brief Overview

28 May 2024

We have developed an online LOLER inspection and certification system

07 June 2024

The Benefits of Recycled Plastic: A Sustainable Solution for the Future

07 June 2024

The Smoking Ban and Workplace Compliance: A Guide for Businesses

19 September 2024

Cycle to School Week: Encouraging a Healthier, Greener Future